This is my first attempt to post pictures with my very limited computer skills-hope it works.

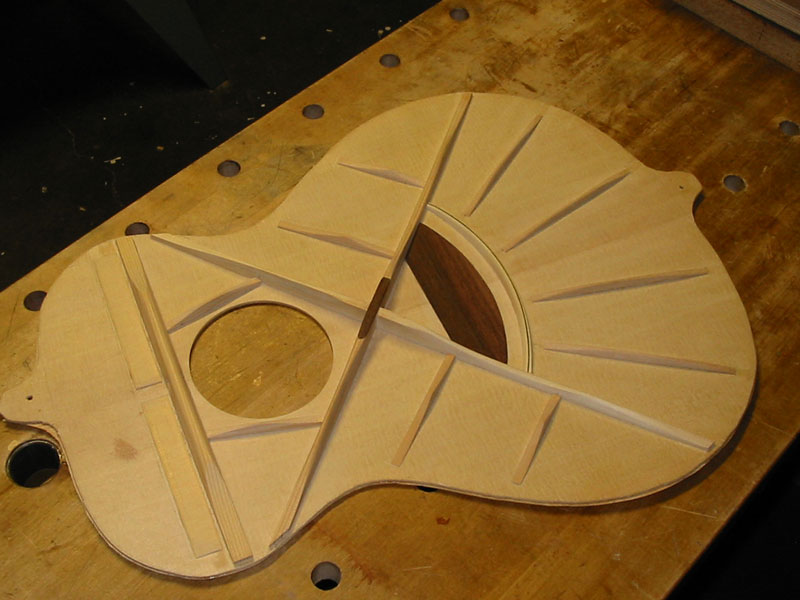

It seems there have been a lot posts recently about bracing patterns, so I thought I would add the two I am working on now. The one on the left is a Carpathisn spruce top for a 14 fret OOO/GC, the one on the right is a Port Orford cedar top for a 13 fretter.

I've only built one other guitar with double X bracing, but it turned out well so I think I'll stick with it for a while.

Paul Harrell

?!?!?!?!?!

?!?!?!?!?!

I have now started experimenting with 100. I read that in Grit's inlay book. He has an article at the start of the book where he tells a bit about his building.

I have now started experimenting with 100. I read that in Grit's inlay book. He has an article at the start of the book where he tells a bit about his building.